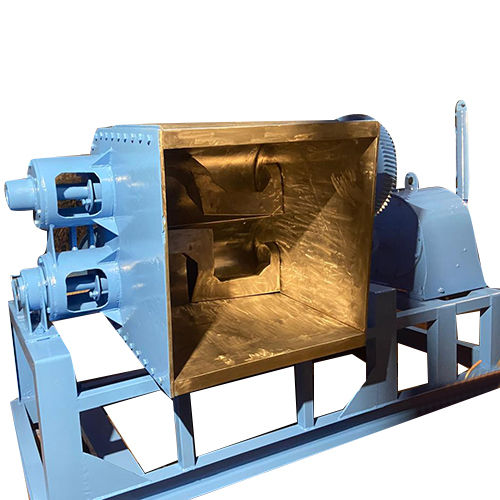

Attritor Mill

Price 750000 INR/ Piece

Attritor Mill Specification

- Usage

- Industrial

- Surface

- Powder Coated

- Attributes

- Easy To Operate

- Power Source

- Electric

- Color

- Blue

- Portable

- No

- Warranty

- Yes

- Material

- MS

Attritor Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 5-10 Days

About Attritor Mill

Equipped with durable grinding media and a robust motor the Attriter ensures continuous operation delivering consistent results even with hardtogrind materials The adjustable speed and pressure settings allow for precise control over the milling process making it ideal for research and production applications alike Whether you need to achieve fine powders slurries or suspensions the Attriter offers an efficient and reliable solution

Key Features

Highefficiency grinding for fine and ultrafine particle sizes

Continuous operation with high throughput

Durable and corrosionresistant construction for longlasting use

Adjustable speed and pressure for precise control over the milling process

Versatileideal for both smallscale laboratory work and largescale industrial production

Low maintenance and easy to clean for minimal downtime

Efficient Industrial Performance

Our Attritor Mill is engineered for continuous and high-output industrial operations. With state-of-the-art electric power system and strong MS construction, it stands out for its reliable performance and ability to handle tough grinding and mixing tasks in various sectors such as chemicals, paints, and minerals.

Quality Construction and Design

Designed with a powder-coated finish for corrosion resistance, and fabricated from superior mild steel, this blue Attritor Mill offers both durability and visual appeal. Its stationary build ensures stable operation, perfect for demanding industrial settings where safety and longevity are essential.

FAQ's of Attritor Mill:

Q: How does the Attritor Mill operate in industrial applications?

A: The Attritor Mill utilizes an electric power source to efficiently grind and mix materials, making it suitable for industrial usage where high throughput and consistent quality are required.Q: What materials can be processed using the Attritor Mill?

A: This mill is capable of handling a variety of materials, including chemicals, minerals, and other industrial components, thanks to its robust MS construction and effective grinding mechanism.Q: When should the Attritor Mill be chosen over other types of mills?

A: The Attritor Mill is ideal when fine particle size reduction and homogeneous blending are needed, especially in continuous or high-volume operations where efficiency and reliability are priorities.Q: Where is this Attritor Mill manufactured and supplied?

A: This product is both manufactured and supplied in India, ensuring easy access to customer support, spare parts, and technical assistance for local industries.Q: What is the process for operating and maintaining the Attritor Mill?

A: Operating the mill is straightforward due to its easy-to-use design. Regular maintenance involves routine cleaning and inspection, as outlined in the user manual, and is supported by the included warranty.Q: How is the usage of the Attritor Mill beneficial for industrial processes?

A: The mill enhances industrial processing efficiency by providing rapid, uniform grinding and mixing. Its dependable operation and durable build minimize downtime, resulting in improved productivity.Q: What warranty and after-sales support does the Attritor Mill offer?

A: The product comes with a warranty, giving customers confidence in its quality and reliability. Local manufacturers and suppliers in India provide comprehensive after-sales assistance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paint Making Machine Category

SS Bead Mill Machines

Minimum Order Quantity : 1 Unit

Power Source : Electric

Usage : Industrial

Surface : Painted

Color : Blue

Sigma Mixer Machine

Minimum Order Quantity : 1 Piece

Power Source : Electric

Usage : Industrial

Surface : Powder Coated

Color : Any Color

SS Bead Mill Machine

Minimum Order Quantity : 1 Unit

Power Source : Electric

Usage : Industrial

Surface : Powder Coated

Color : Blue

Paint Filling Machine

Price 400000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Usage : Industrial

Surface : Powder Coated

Send Inquiry

Send Inquiry